Environmental Compliance Management: What Your Enterprise Needs to Know

Before joining Mapistry, I once held a position as a contractor to a large, three-letter federal agency. I was the sole person dedicated to environmental compliance in the organization, which included over 300 facilities spread across 20 regions with well over a hundred Spill Prevention, Control, and Countermeasure (SPCC) plans and dozens of Stormwater Pollution Prevention Plans (SWPPPs) and air permits.

With operations including fleet fueling, vehicle, boat, and aircraft maintenance, and hazardous waste generation from live-fire exercises, it’s easy to imagine how the complex layers of federal and state regulations and the immense bureaucracy were challenging to navigate.

These challenges are not unique to the federal government, and I’m sure some of them sound familiar to our customers and readers who are corporate environmental managers.

With many large businesses pursuing ISO 14001 certification or implementing an Environmental Management System (EMS), this post aims to help those managers dealing with environmental compliance at the enterprise level and across many sites.

The Challenge of Managing Environmental Compliance at the Corporate Level

First, I want to take a step back and recognize the limitations of managing compliance while sitting at company headquarters. Having so many facilities under your umbrella (you may never see in person) means you’ll need some help on the ground. I had some great regional facility managers to work with but, as you can imagine, they were constantly putting out fires, were too busy to focus on environmental compliance, and had little budget. Fortunately, requiring ISO 14001 environmental audits of every facility on a rolling three-year basis forced the agency to pay attention to compliance.

The challenge was entering the audit findings into an integrated workplace management system (IWMS), managing the data, and finding a way to fix the issues.

Every audit cycle would identify thousands of missing records, expired spill kits, sampling, and inspections that were never conducted, SPCC plans and SWPPPs that were outdated or missing entirely, instances of hazardous waste thrown in regular trash, lack of training, etc… After entering the IWMS, it usually falls to environmental managers to remediate each deficiency, often from a distance, and without disrupting operations or spending too much.

So I did what many corporate managers would do, and built spreadsheets. I tracked which facilities had the most glaring issues, which had direct safety risks, and which had the most low-hanging fruit. I also built cost models that allowed us to more efficiently target where to hold training sessions or send equipment and outside contractors.

I’m guessing this will sound familiar to many of you, as the industry has largely failed to leverage technology effectively. Maybe you’ll even make great progress on closing out audit findings this way, but the results of subsequent audits might reveal that you’re only addressing the symptoms and not the disease.

Training and turnover were particularly difficult problem areas. It’s tough to train and get non-environmental staff to take compliance seriously when they don’t have an environmental role or background.

You probably have an enterprise learning management system (LMS) where employees can click through courses on environmental awareness, hazardous materials handling, SPCC, or even stormwater management. While these modules can contain good high-level information, most folks don’t pay much attention during online training.

Not only that, but SPCC and stormwater training must be site-specific, meaning you’re not meeting the letter of the law or the requirements of your permit or unless your environmental managers are putting together facility-specific slide decks and visiting each one annually (or finding a vendor to do it, at great cost).

A lack of continuity in facility staff was a challenge not only for the training program but overall records retention (what records?) and awareness of compliance requirements by non-environmental staff. All this to say that environmental audits, while necessary and beneficial thanks to the legal risks facing the industry, often leave a business with many deficiencies that are difficult to solve from the corporate suite.

More and more often, businesses identify their suppliers as part of their overall environmental risk and subject their partners to additional third-party audits. And after discovering instances of non-compliance, you are obligated to correct them ($$) or else it’s a willful violation, exposing your organization to citizen lawsuits, significant financial penalties, and other risks ($$$$). Even those of you working in low-risk industries are not exempt, as it’s more likely your facilities have no environmental professional on site, increasing the chance something will be missed. We know environmental budgets are always tight.

Traditional consultants exacerbate this lack of funds by charging hourly at senior billing rates for work done by entry-level staff.

You’re also paying the transactional costs of buying consulting services: the time and effort you spend on the procurement process.

If each of your facilities has to solicit quotes from local companies every time there’s an issue, remedial efforts are even slower. You may have master service agreements with one or several environmental consultancies, giving you a smoother process and internally pre-approved vendor options. But if you ask me, continually buying one-off services is not just costing you money, but is a sign that your compliance program is inefficient, not up to par, and reactive.

How to Achieve Compliance Excellence Enterprise-Wide

Due to increasing stormwater litigation risks, it’s no surprise that environmental awareness has reached the corporate suite at industrial companies.

Second to cultivating a culture of accountability, involving top management at your company in environmental compliance is the best place to begin. Knowing you have the backing of corporate leaders to make compliance a priority can give you greater autonomy in budgeting and in committing regional or facility staff to environmental initiatives.

Here’s some additional advice from my past experience, where we were able to increase audit finding closures from 35% to 92% within a few years.

- Develop your own internal (bottom-up reporting/top-down feedback) and external (regulators) communication processes. Emphasize transparency and the timely sharing of bad news.

- Implement an internal audit program with defined schedules and processes, and have well-trained auditors.

- Present audit findings to employees. Operators and process employees should be aware of improvement opportunities as this is a main driver of value for internal audits.

- Your environmental managers should be armed with the best training materials and techniques. Have company leaders show up at environmental training sessions to say a few words, driving home the importance of compliance at all levels.

- Buy in bulk and get volume discounts. For example, identify all facilities that need SPCC updates and get them done in one contract.

- Delegating authority (who can sign a document or make purchases) effectively and liberally will improve response times when issues arise. Due to geography or operations, each facility has different needs and many purchases shouldn’t require corporate review.

- Keep your records! Everyone knows this, why is it so hard? They need to be both retrievable on-site and centralized for you, the manager. Paper-based recordkeeping is far from efficient, but I found that storing environmental documents next to SDS binders at Right-to-Know stations (not tucked away on a shelf) and including this in regular safety briefings helped improve awareness.

- Show continuous improvement and don’t sit on corrective actions. Lawsuits happen when companies take no action on a problem.

- Make a full accounting of your environmental compliance spending. With facilities operating independently, it’s hard to show the value of your program and even harder to justify major changes that reduce risk and liability.

- Show cost-consistency in your compliance budget. Emergencies aside, producing an accurate and repeatable budget will ensure you get the cash you need to maintain compliance even if business is slow.

These strategies mitigate but don’t solve the challenges of managing compliance across dozens of facilities. Unfortunately, environmental managers have few options for gaining instant visibility into compliance status across all their sites. With all the delays in information flow that happen in a large organization, it’s no wonder that compliance efforts are often too reactive.

It’s time for an organized, programmatic, and proactive approach to enterprise compliance

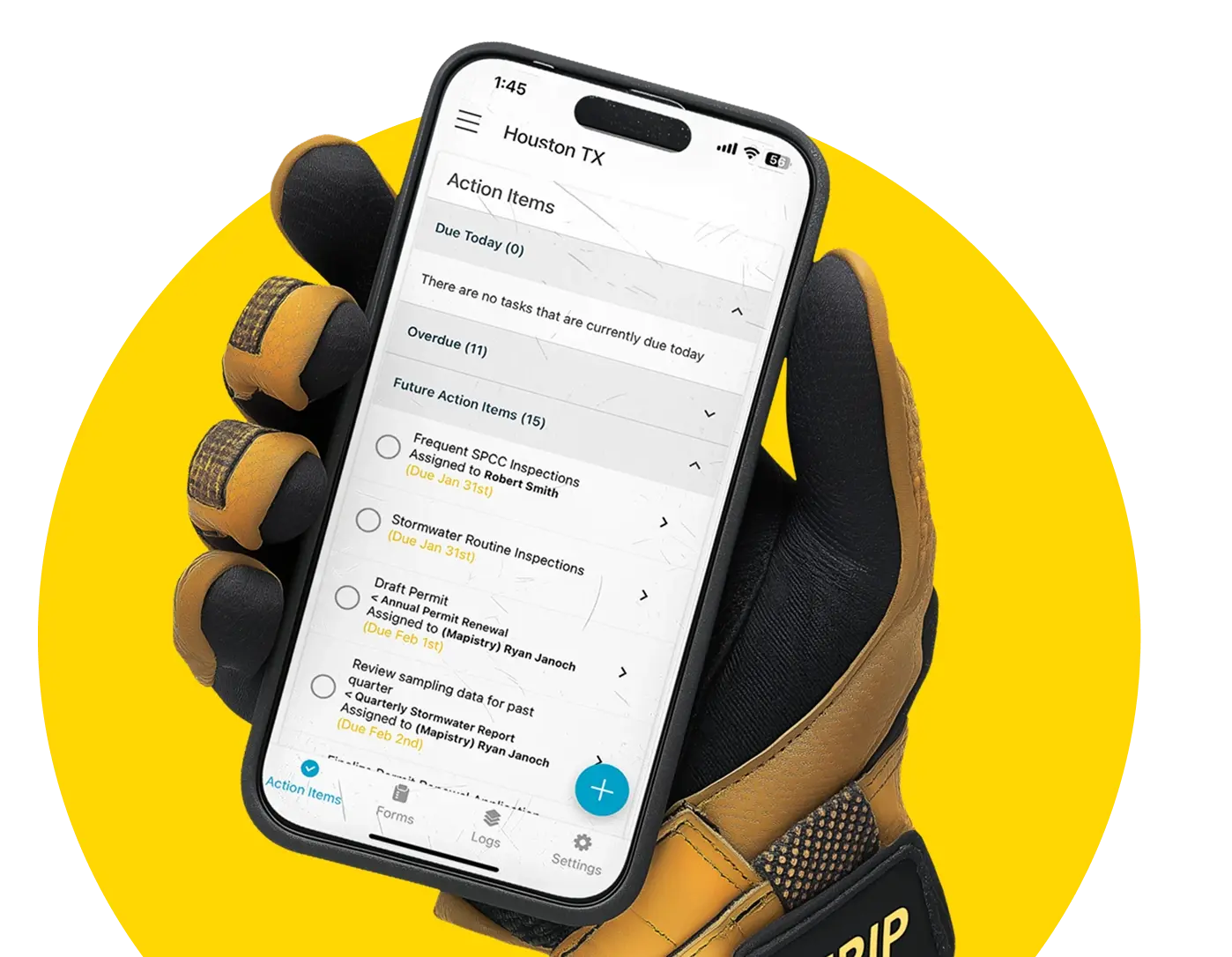

ISO 14001 requires enormous effort, and stormwater or SPCC programs can easily get lost in the shuffle. We know what it takes for large businesses to answer the mail and see the need for a better way to manage an environmental compliance program. Mapistry’s organizational dashboard caters specifically to environmental managers and executives managing multiple sites. It provides real-time analytics to identify trends, highlight problem areas, assess performance, and close the loop on corrective actions across your entire organization.

Integrating records, deficiencies, lab data, weather, and mapping means we’re way more than a typical facility asset management system or safety incident tracker. Mapistry is built from the ground up for environmental compliance and keeps each of your responsibilities (stormwater, SPCC, and hazardous materials) in one place to be centrally managed by you, the forward-thinking program manager.

%201%20(2).png)

.png)

.svg)