The Three Phases of a Successful Environmental Inspection Program

A successful facility inspection program may begin with 100% completion rates, but it doesn’t end there.

An inspection that requires a permit or environmental regulation is the minimum for an environmental or EHS manager, director or VP to measure their team’s success on each day, week, month and year (Phase 1).

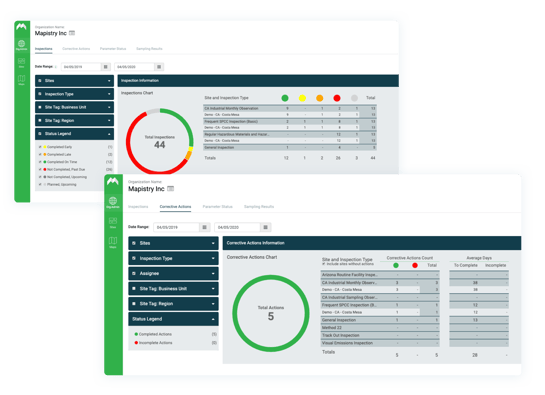

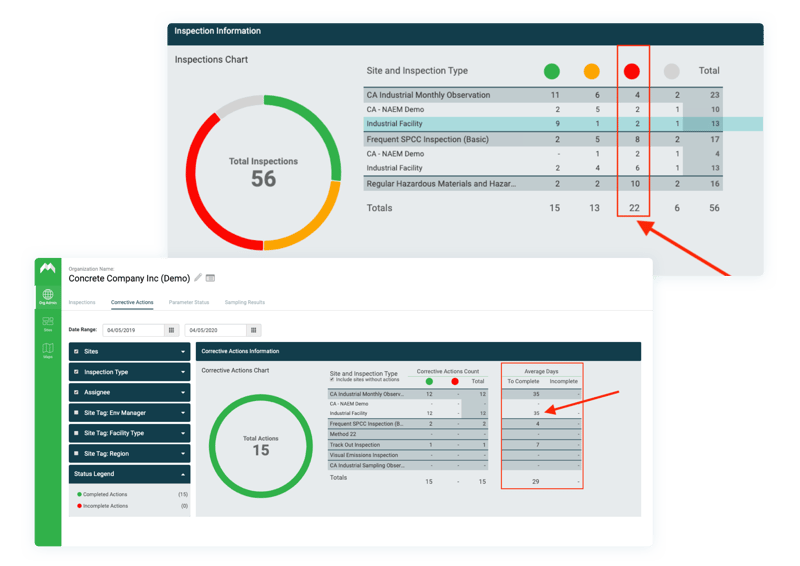

However, a core piece of not incurring fines, accidental discharges, or lawsuits is to focus on other leading indicators that measure the quality of an inspection program, such as corrective actions (Phase 2) and days to close out (Phase 3).

We have all been to many industrial facilities, and dynamic operations, materials, equipment, and control measures often need some love. As companies progress through building an excellent inspection program, they should keep in mind the following steps:

-

Phase 1 – 100% on-time inspection completion

-

Phase 2 – Identify corrective actions (typically 1-2 per inspection)

-

Phase 3 – Reduce the time (e.g. days) to close out corrective actions

Sometimes, environmental managers struggle to hit 100% inspection completion, but over time, with operational leaders' support and a dedicated training program with tools to leverage for notifications and standardization, it can quickly be achieved (Phase 1).

Next up is making sure corrective actions are being identified. There is rarely a facility that can say there are no further actions to take when an EHS manager or operations leader walks around. The key is identifying these corrective actions to address them and showing regulatory agencies your company is actively engaging in the mandated inspection process (Phase 2).

Once a corrective action is identified, Phase 3 of a world-class inspection program is required, closing them out quickly.

For environmental leaders monitoring corrective completion rates (e.g. “days to complete”), they want to see that number below set benchmarks (e.g. less than 5 days) or pushing for continuous improvement of a reduction month over month in days to complete.

The best environmental programs out there strive for 100% completion, the creating corrective actions, and focusing on reducing the time it takes to complete a corrective action.

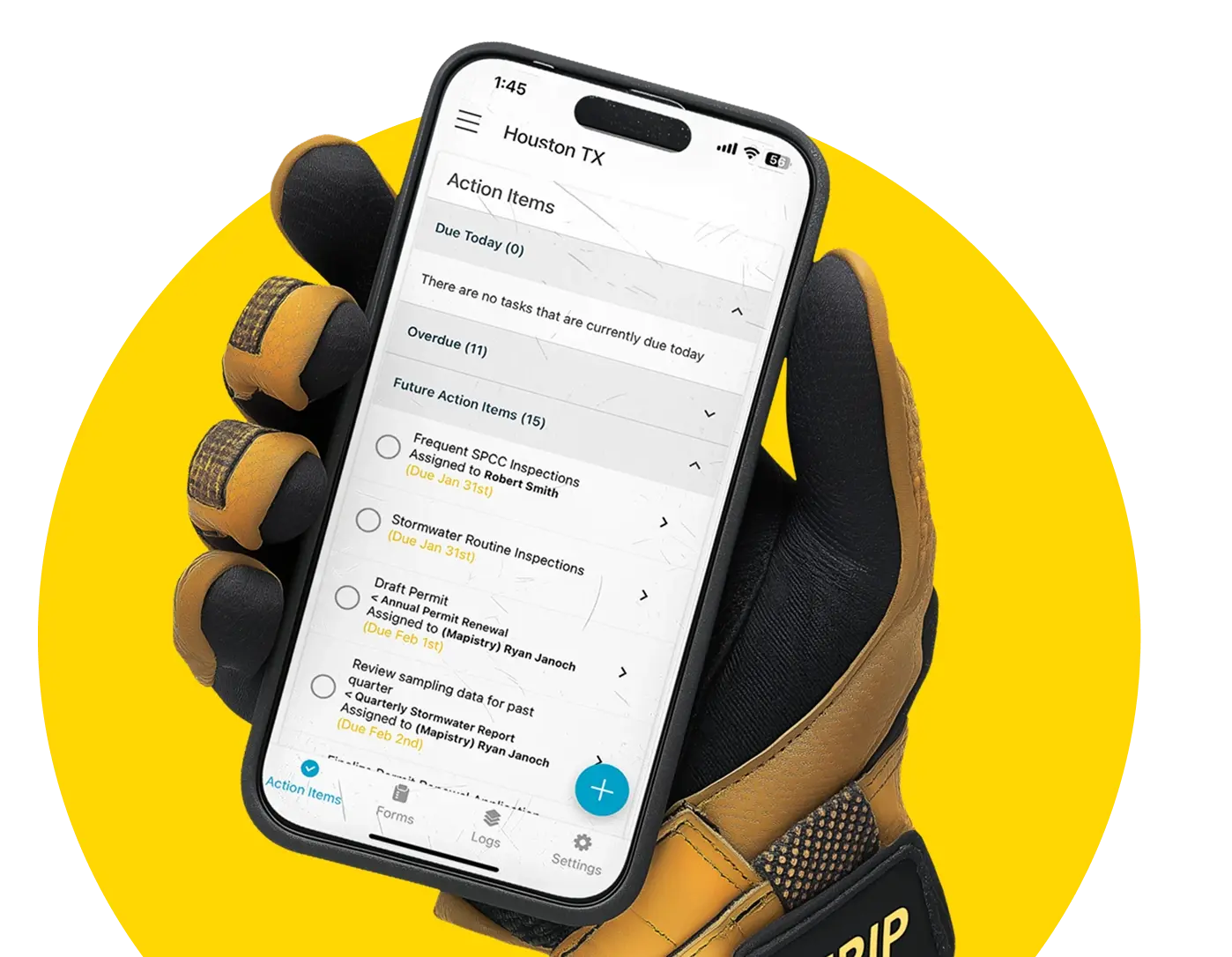

How can you implement all three phases of this program for both site/facility staff so as not to overwhelm them with paperwork and engage with analytics as an environmental or EHS leader? Technology. Utilizing a mobile app that ensures timely completion (e.g. alerts) and automates the routine parts of an inspection (e.g. date, weather, and name) gives staff on the ground an easy way to complete the inspection (Phase 1).

However, identifying corrective actions and not “pencil whipping” an inspection requires a well-trained team. This is the hard part as an environmental manager, but this is achievable through e-learning (probably more than ever now with COVID-19) and in-person training (Phase 2).

Next is the automation of corrective actions (e.g. emails) to the right person to get them addressed quickly with a timely reminder of outstanding ones (Phase 3).

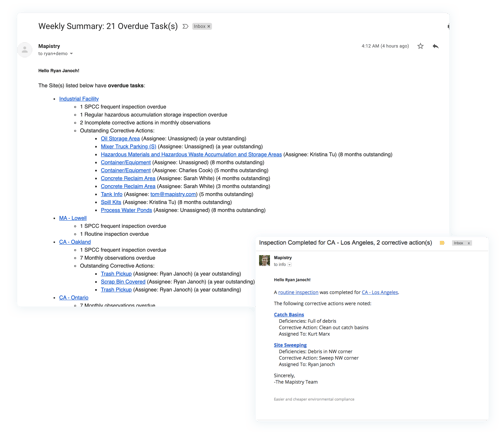

For environmental leaders, the key is monitoring all three phases in real time and using data analytics as a teaching tool to reinforce good behavior. This can be done by monitoring weekly summaries of outstanding inspections and corrective actions with their “days outstanding”.

More important is the routine review of facilities metrics and focusing extra attention on those managers and staff who are struggling.

Technology can tie all these parts together in real-time without waiting a year to flip through a binder at a facility, thus providing an opportunity for leaders to give continuous feedback, ensure leading indicators are being met, and reduce the time spent by operations and environmental staff at the facility level.

%201%20(2).png)

.png)

.svg)