An Overview of SPCC Fines, Penalties, and Lost Litigation

The Spill Prevention, Control and Countermeasure (SPCC) program requirements are among the most intricate yet key facets of running a Clean Water Act-compliant facility.

The EPA issued the first SPCC regulations in 1974 followed by substantial amendments and increased costs in 2002. Unlike similar regulations that are delegated to state and local governments to enforce, SPCC enforcement is managed federally by the EPA’s ten regional offices, which oversee approximately 670,000 facilities, with one 2011 study finding 55% of those out of compliance.

Overview of SPCC Requirements

As a refresher, SPCC applies to non-transportation related onshore facilities engaged in the “drilling, producing, gathering, storing, refining, distributing, or consuming [of] oil or oil products”. The EPA broadly defines what is considered an oil product . Facilities involved with “fats, greases, and oils with animal, fish, vegetable, mineral, or synthetic origin” most likely need an SPCC plan.

The current requirement for facilities needing to develop a plan include those with a minimum of 1,320-gallon above-ground oil storage capacity (or 42,000 gallons in underground) or even with a “reasonable expectation of oil discharge to waterway”.

Typical SPCC plans require facilities to adopt mitigation measures, including descriptions of drainage control devices, equipment preventing discharge, and adequate secondary containment (such as trays, berms, or dikes) around holding tanks to prevent a release to the environment in the event of a spill.

Further, plans require approval from a professionally licensed civil engineer and must contain provisions that address issues such as training, preventative maintenance, and facility security. The only industries not required to have an SPCC plan include those far removed from large bodies of water, facilities with equipment already controlled by another regulatory program, and those that store less than 43,320 gallons in combined tank volume.

Among the nearly 700,000 regulated facilities, a small portion (<1%) of higher-risk facilities determined to “reasonably cause substantial harm to the environment” are required to prepare and submit Facility Response Plans , which involve extra guidelines that undergo EPA review. Additionally, all facilities must self-certify whether the FRP applies to them based on spill history, lack of adequate secondary containment, and proximity to drinking water intakes and/or environmentally sensitive habitats.

SPCC Fines and Penalties

Failure to follow all steps can result in facilities paying over $32,000 a day with total penalties adding up to $40,000 if proper corrective actions are not taken.

While it is fairly obvious that not having an SPCC plan at all constitutes a major noncompliance, failure to review your plan after 3 years, modify your plan with each facility upgrade, or certify amendments can be grounds for fines that can start at $1,500 – even if no spill has occurred! Clean Water Act Section 311(j) outlines the process of determining the seriousness of the environmental risk due to a violating spill. Risk of a potential violation is determined by the extent of the violation, likelihood of a spill, and environment sensitivity.

The severity of a violation depends on the storage capacity of the violator’s facility, existence, and adequacy of secondary containment and duration of the violation. One 2013 study determined that the EPA most frequently fined facilities for failure to keep 3 years’ worth of SPCC records, failure to train personnel on their facility’s plan, and inadequate mechanical inspections. In cases where a spill results from gross negligence or willful misconduct (B.P. Oil Spill – lest we forget), a type of judicial forum is required with the minimum penalty starting at a hefty $100,000.

Examples of Facility SPCC Litigation Losses

Being unaware of the nuances within SPCC requirements could add headaches and costly litigation. In Pepperell Assocs. v. United States EPA, 246 F.3d 15 (2001) for example, the Environmental Appeals Board held that Pepperell could not be excused from failing to have a spill control plan while installing an oil storage tank.

Pepperell was fined for spilling 300-400 gallons of oil from one of its textile mills into the navigable waters of the Androscoggin waters near Lewiston, Maine. Pepperrell argued that the discharge of oil was not “reasonably foreseeable” and thus outside the purview of the SPCC regulations.

On review, the Court of Appeals for the 1st Circuit denied Pepperell’s petition on the basis that it was, in fact, “foreseeable” for oil to leak in multiple possible pathways, not just one path that Pepperell relied on. The EAB found Pepperell ultimately liable to pay a $44,000 penalty and ruled that an SPCC plan must be amended within 6 months whenever existing facilities are modified. In another case, United States v. Jones, 267 F.Supp.2d 1349 (2003) summary judgment was granted in favor of the EPA on the claim against oil processing facility owners (Jones) for failing to have an SPCC plan, resulting in discharges in violation of the Oil Pollution Act (OPA).

There, the facility owners failed to periodically test above-ground tanks nor followed proper containment protocol for tank loading and unloading. But for a minor inconsistency, the facility owners narrowly escaped paying $2.5 million dollars incurred by the government clean up of the spill because each party responsible for an oil discharge is obligated under the OPA for removal costs. More recently, in API v. Johnson, 541 F.Supp.2d 165 (2008) plaintiff oil companies sued the EPA under the Clean Water Act and Administrative Procedure Act for promulgating (establishing) overly broad revisions of “navigable waters”, which resulted in them having to suddenly pay millions to enhance their SPCC plans around their facilities.

The court sided in favor of the oil companies on the basis that the EPA violated the APA for failing to provide sufficiently clear and supported explanations for its expansions. The outcomes in Pepperell, Jones, and API represent both the ever-expanding complexity of SPCC regulations and how misinterpreting SPCC regulation implementation can result in thousands of dollars in penalties and legal fees.

How Can You Reduce Your Risk?

In recent years, the EPA has been particularly vigilant about targeting oil spills near water, regardless if the spill comes from a pipeline, a boat, by rail, or some other source.

Typically, SPCC violations can be categorized into six main categories, including problems with the plan itself, failure to inspect facility, inadequate training, issues with storage tanks or drainage, and generally lackluster facility operations.

Earlier this year at the Energy and Environment conference in Connecticut, attorneys Rachel Rosen and Richard Fil urged industry experts to embrace a more practical, communicative approach to improving spill prevention.

The panel particularly appealed to stormwater industry experts and was intended to provide commonly overlooked considerations to go above and beyond SPCC compliance in order to increase efficiency and minimize the consequences of potential spills. Some of less-than-intuitive recommendations in reporting requirements include:

- Informing corporate entities and insurance companies,

- Distributing laminated guides for employees that outline spill response assignment

- Considering sources not covered in an SPCC plan, such as equipment that doesn’t normally contain oil (circulators, pumps, relief valves, and secondary containment).

- Quantification and recording of amounts released in a spill and amounts recovered as some agencies may reduce fines if a significant amount of the spill can be accounted for.

Fil of the international law firm Robinson + Cole stressed the importance of fostering good communication by maintaining attorney consultant confidentiality and even integrating communication drills among staff into spill response plans.

Check out our blog from last month and get up to speed on the EPA’s response to potential SPCC rule changes brought on by massive litigation. We will continue to update our readers as a final decision is reached. Stay tuned!

Next Steps?

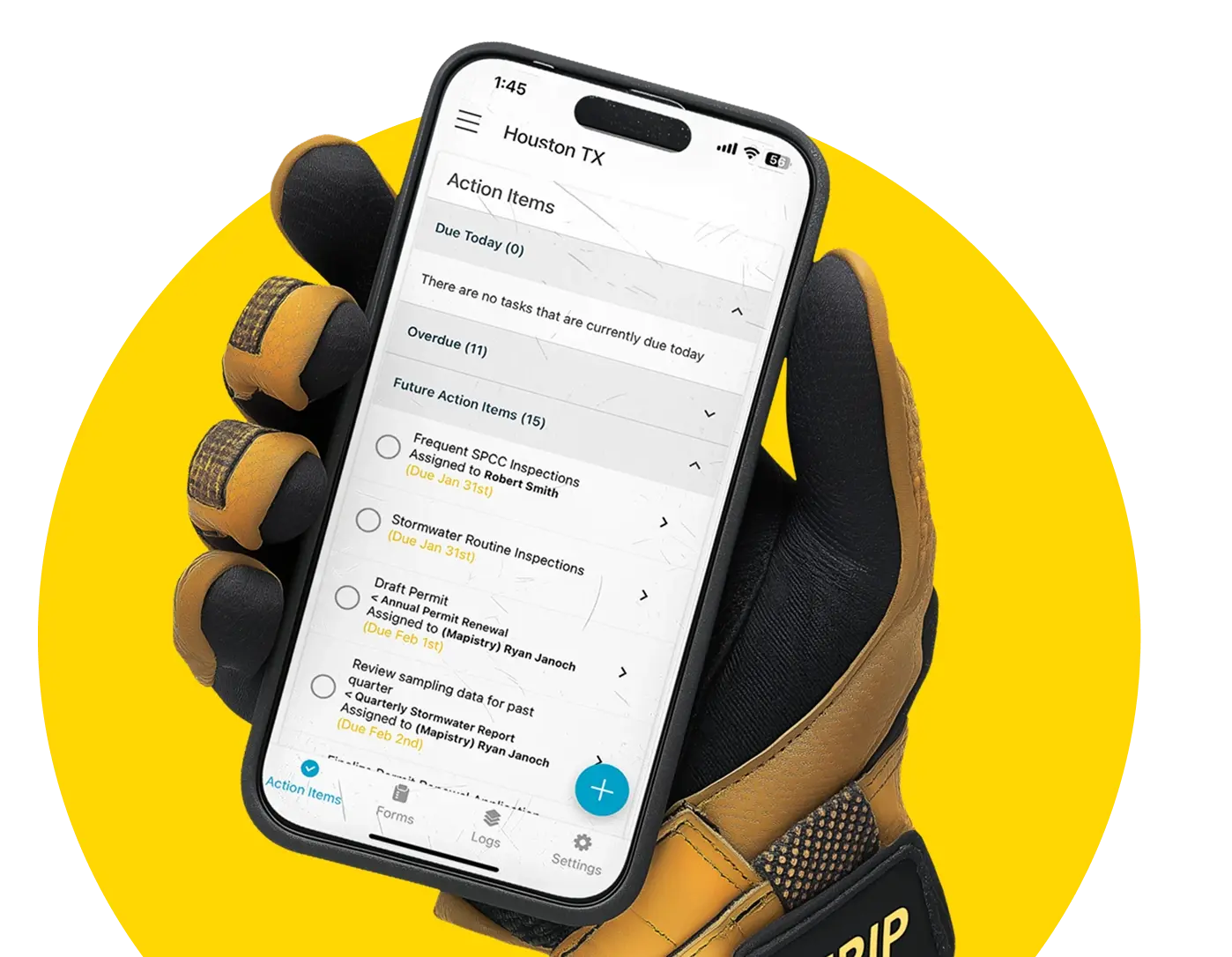

If you need help navigating SPCC regulations, Mapistry offers a digital SPCC platform to keep manufacturers compliant with minimal effort.

%201%20(2).png)

.png)

.svg)