Automate environmental data collection

Tired of punching data into permit limit spreadsheets? Get your life back with automated data collection, AI-assisted uploads, and mobile data entry.

Data entry?

Never again

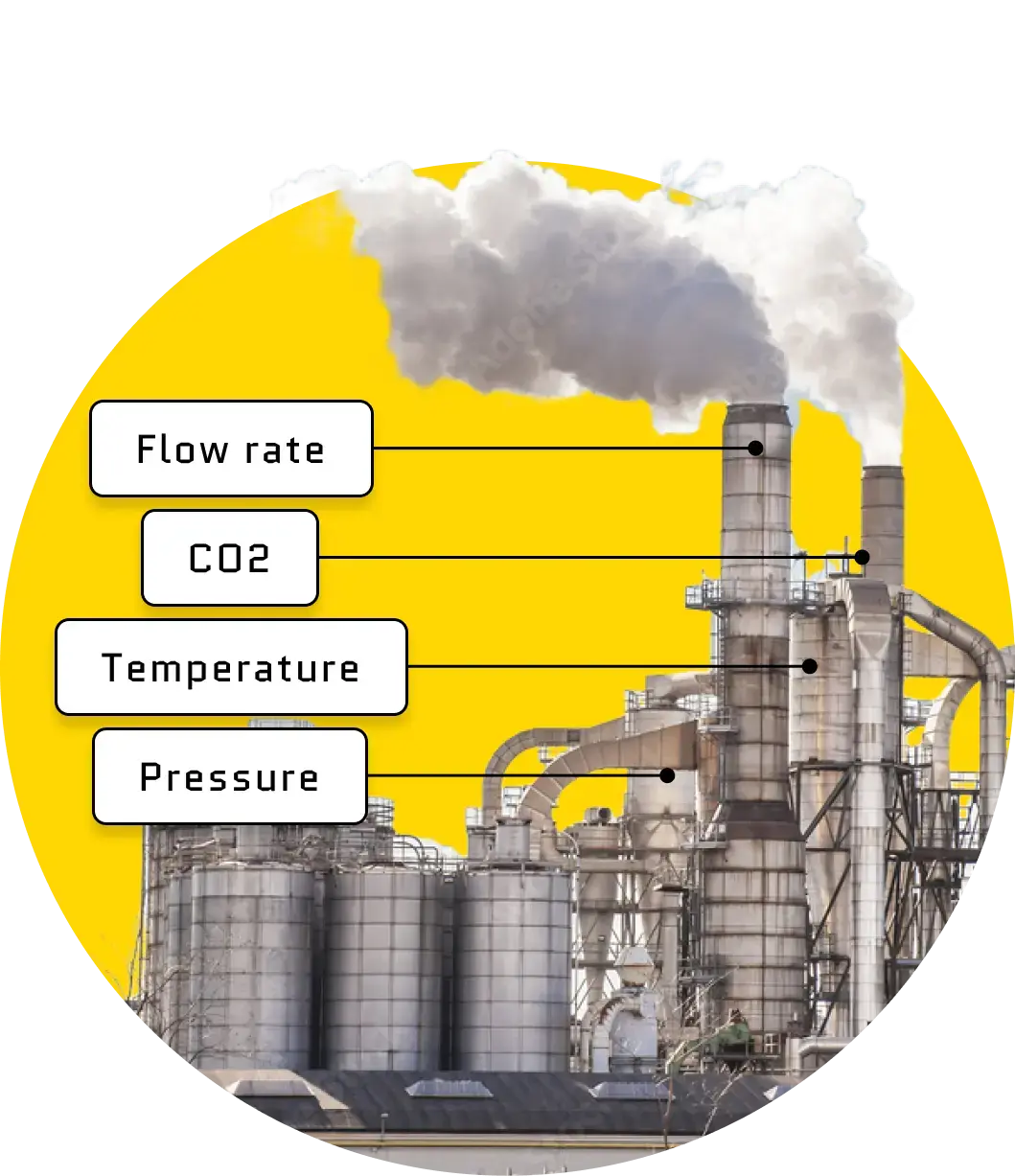

Tap into data from your existing systems

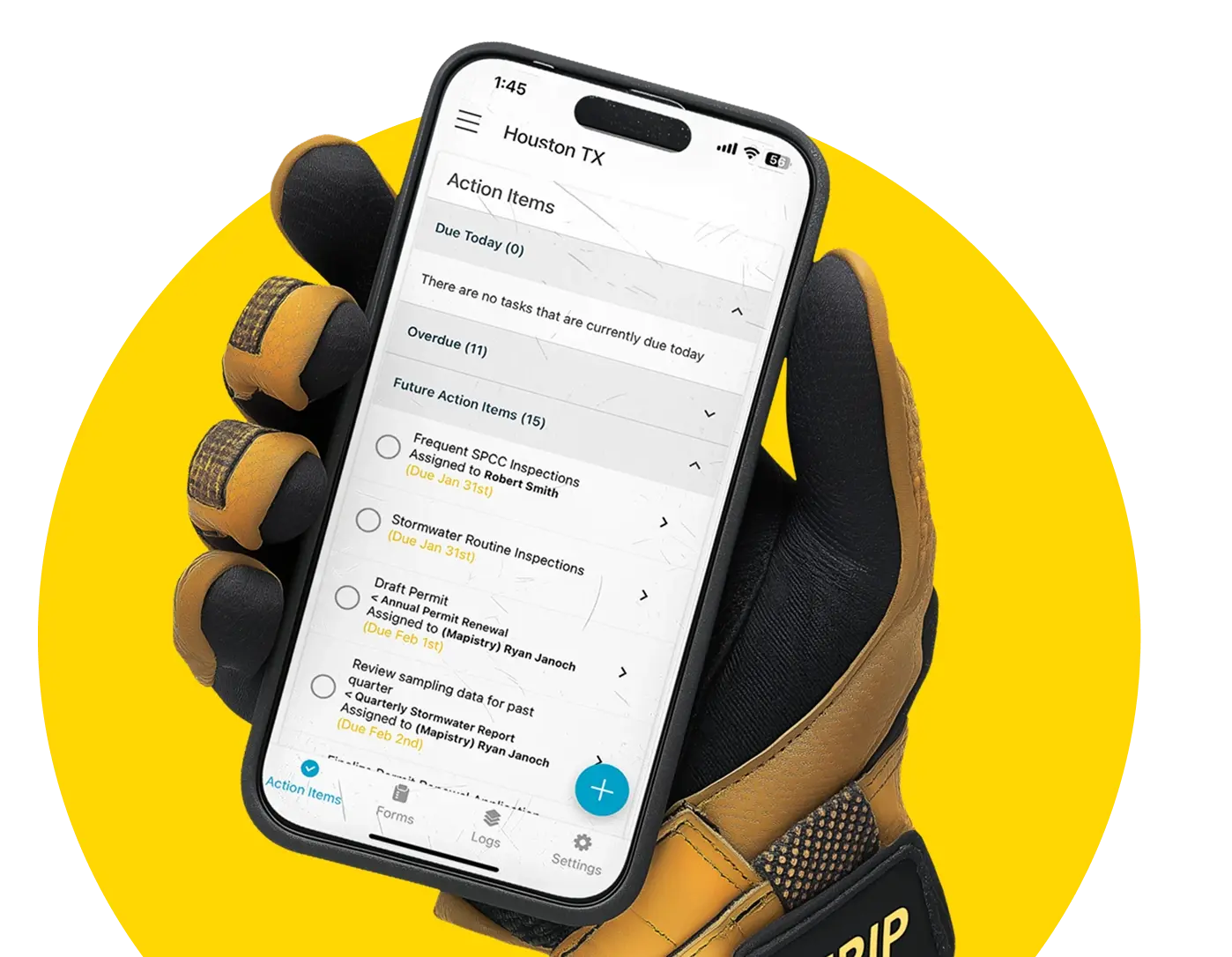

Mapistry centralizes communication and task management, so you can finally ditch those endless email chains.

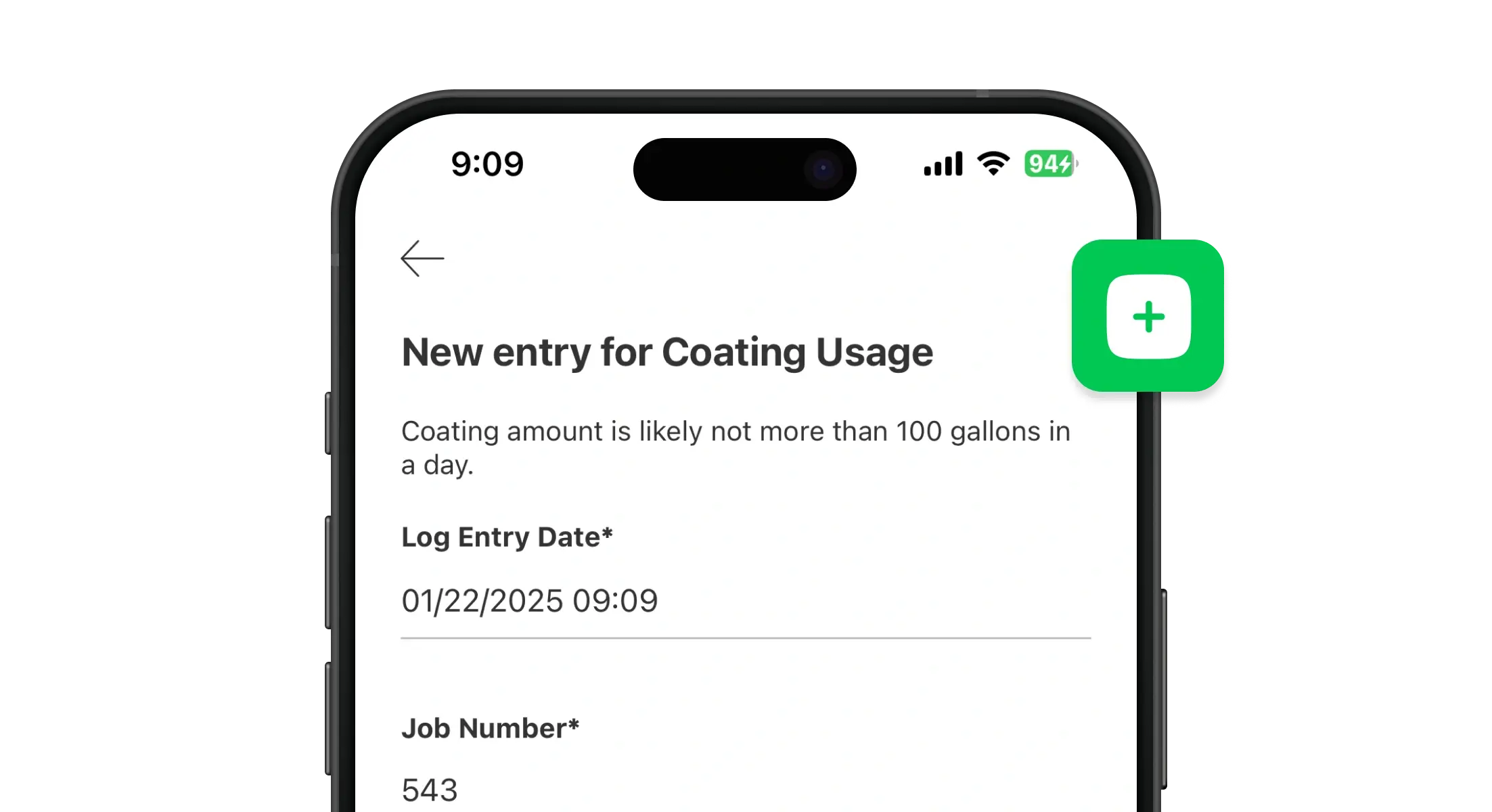

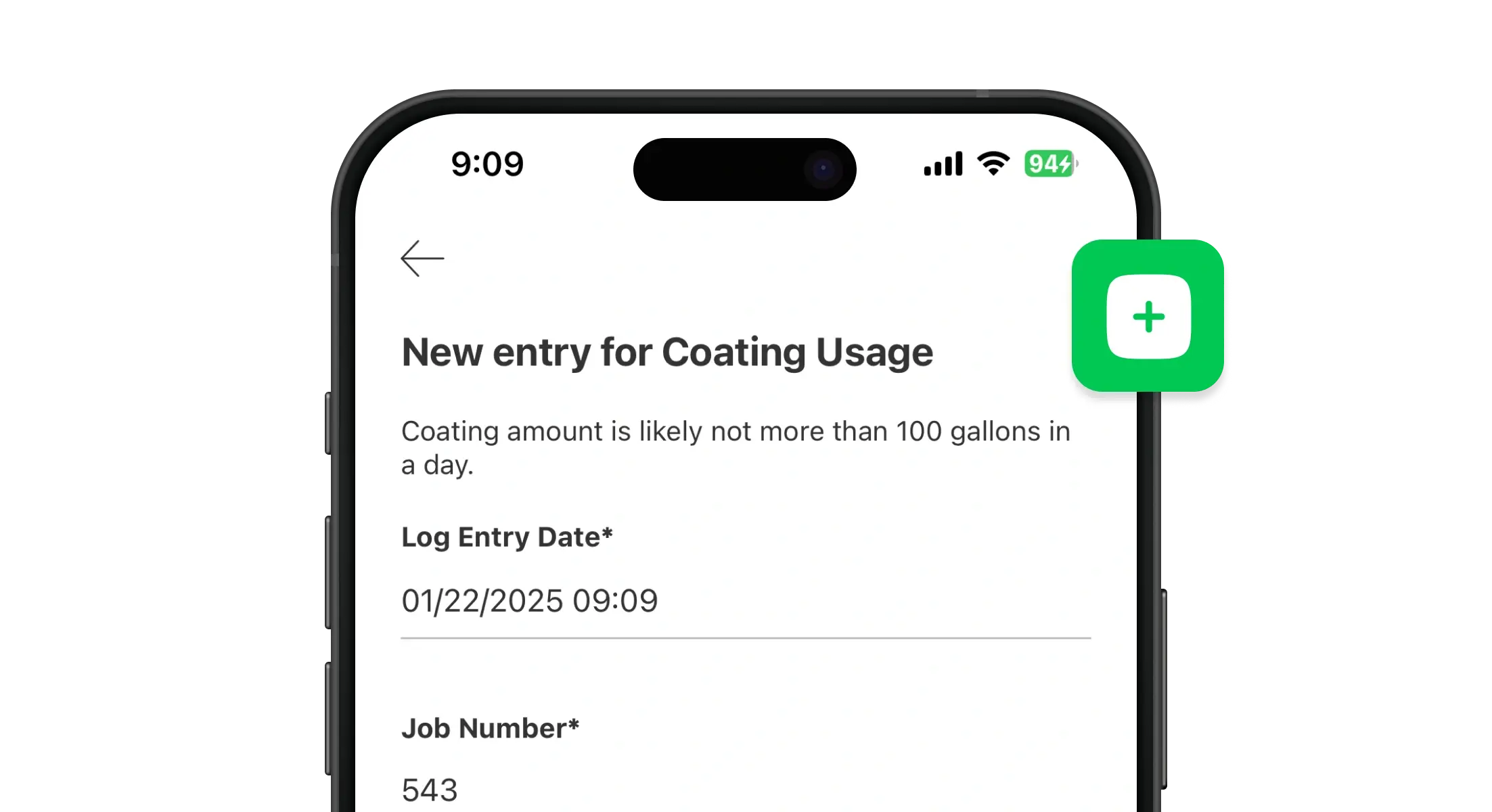

Easily log data on the go

Stop chasing down data from operations. Mapistry’s intuitive app lets them log data from the field, easy as pie.

It’s less work for everyone, and your data is always up-to-date.

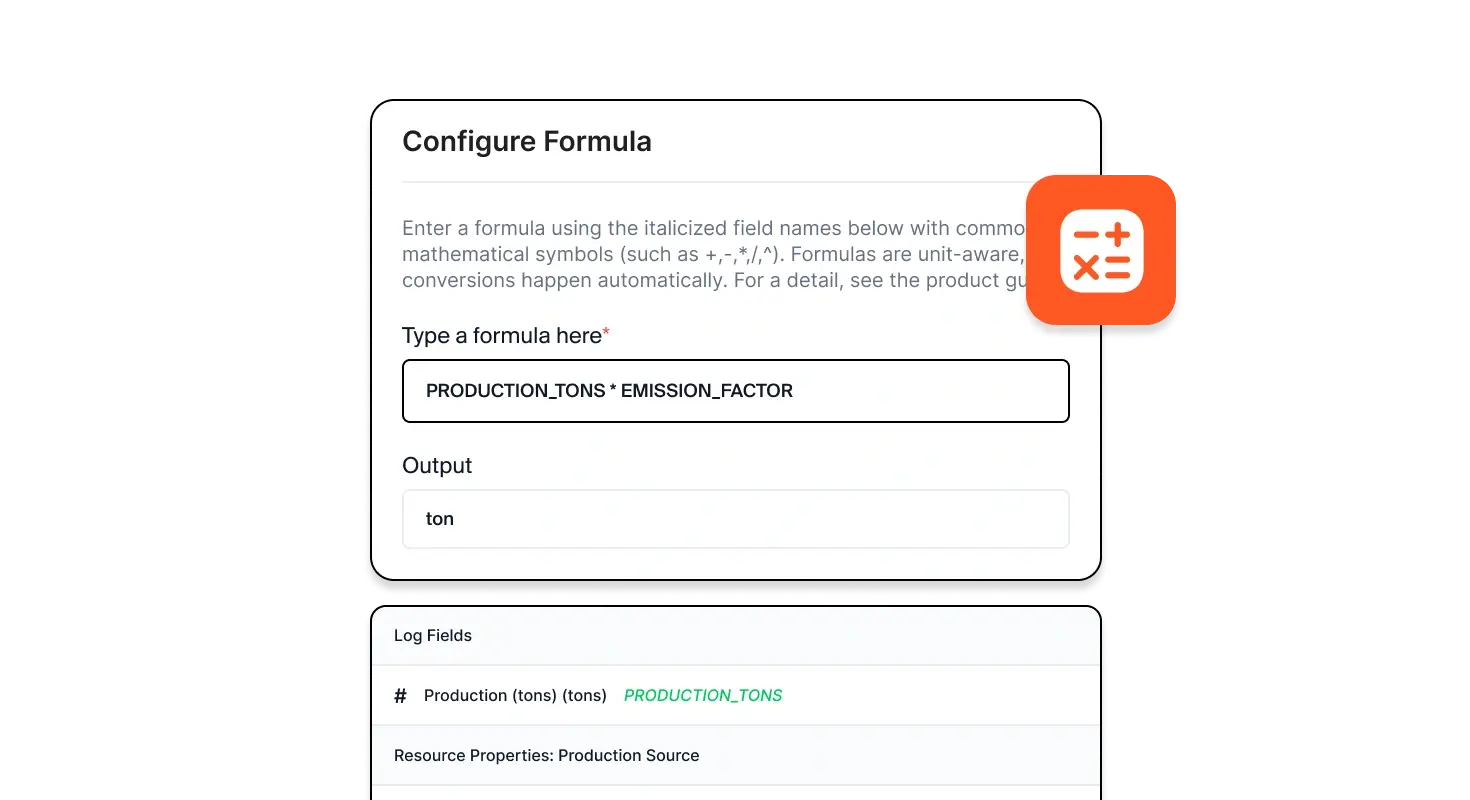

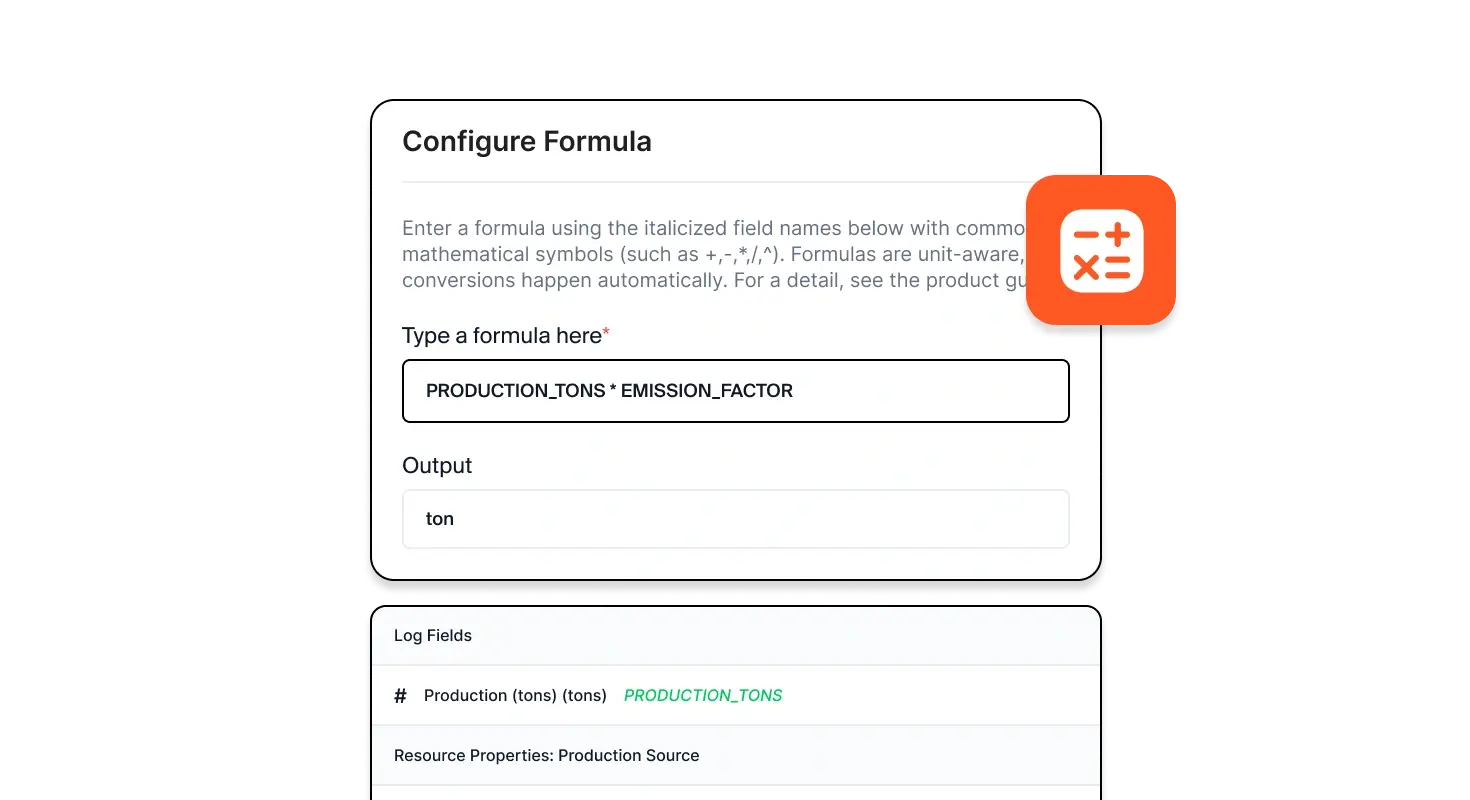

Create calculations, easy as Excel

Love tracking permit limits in Excel? Great!

Mapistry’s formula builder makes it just as easy and has error-proofing built in.

Get alerted before crossing limits

No more accidental limit exceedances. Mapistry automatically sends you an email alert when you're close to hitting your limits.

.webp)

Always ready for reporting season

All your data is already stored in Mapistry. No need to chase down operations.

Just export your data to Excel and submit it to regulators. Reporting season has never been easier.

.webp)

.webp)

.webp)

Learn how you

can use this capability

.svg)

Automatically collecting data from your systems

Watch tutorialAutomatically collecting data from your systems

Field Readings - Generator logs & Baghouse readings

Watch tutorialField Readings - Generator logs & Baghouse readings

Environmental compliance for industrial facilities

Generic EHS tools do “a little of everything”. We exclusively focus on environmental compliance for industrial facilities.

Discover more capabilities

Automated Data

Collection

Mobile

Inspections

For air, water, and waste compliance

%201%20(2).png)

.png)

.svg)

.svg)