The tools and methods for regulatory inspections and audits have changed. Regulators can successfully use aerial imagery services, digital record requests, video conferences, or even drive-bys to audit a facility –never stepping foot on-site, and even at times, without ever speaking with your site manager. I recently had the pleasure of discussing at the Texas Aggregates & Concrete Association (TACA) Environmental & Sustainability Seminar how in the past, paper worked, there were simpler rules, with minimal oversight. Yet, today, with remote and stealth audits, the speed, complexity, and consequences of being compliant outpace the bandwidth of compliance staff. With sharper legal and financial consequences, and more complex regulations, your team needs greater connection to the data in real-time and digital compliance to be audit-ready in a post-COVID world.

The Audit Challenges

The move toward remote inspections means that facilities need to re-evaluate their internal tooling and prepare for new auditing styles.

COVID-19 impact

Technology shifts at the onset of COVID-19 allowed for many businesses to keep going in a safer, virtual/distanced environment. Trucking dispatch quickly turned to contactless digital solutions to track shipments and keep their operations running smoothly. EHS regulators too began using technology. However, with the advancement to remote audits and their use of technology, the resource constraints on operations and environmental staff became glaringly apparent. Even when fully staffed, compiling and analyzing the data obtained from daily compliance reporting is a massive time investment. Add in the impacts of staff turnover and reduction due to the pandemic, and the lack of technical expertise to interpret the results and understand the data to mitigate risk — the accelerated shift to digital greatly exposed the demands that the traditional process can not keep up.

Enforcement increases

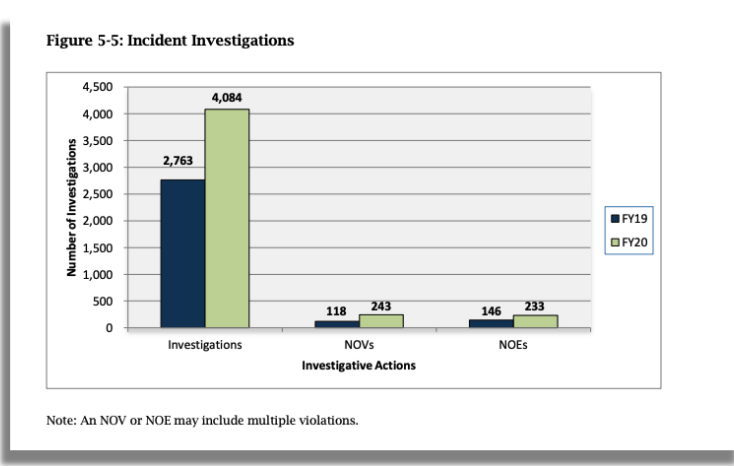

In April 2021, the EPA announced its goal to increase the number of facility inspections in overburdened communities, embracing the use of remote and digital tools. Case point: The Texas Commission on Environmental Quality, found that despite social distancing in 2020, the number of investigations conducted under 30 TAC Chapter 101 increased from 2,763 in 2019 to 4,084 in 2020. Further, under the Biden Administration’s focus on environmental justice, we’ve seen wider recognition that non-compliance is common . With governing guidelines placing much stricter scrutiny of compliance programs, and a more aggressive shift to ‘Next Generation Compliance’, everyone is forced to take greater responsibility and accountability in the environmental impact of their operations.

Public data is a priority

The shift to public data has been forthcoming. In 2019, Executive Order 1389 directed federal agencies to make guidance documents available online. The EPA launched an improved online portal to provide the public with access to see the trends of compliance programs at the national, state, and local level. This gives everyone access to see information such as violations and actions taken. Further, the SEC adopted policies requiring disclosure of ESG risks, and investors have made an appeal to ensure that they, along with regulators and the public, have greater insight into how companies are managing EHS.

What’s at stake? The risk of non-compliance.

With the greatest risk the impact on the environment, safety, and sustainability for your community, non-compliance comes at a high price — both in penalties/lawsuits from the enforcing government agencies, and the threat of citizen suits from environmental organizations. In December 2020, the EPA amended its level of the maximum (and minimum) statutory civil monetary penalties to a formula that annually adjusts the amount of penalties and promotes compliance with the set forth regulations. Under this formula, looking at just the mitigation of potential penalty costs, violations of the stormwater permit can result in a $56,460 fine per day.

“The EPA’s civil penalty policies, which guide enforcement personnel on how to exercise the EPA’s discretion within statutory penalty authorities, take into account a number of fact-specific considerations, e.g., the seriousness of the violation, the violator’s good faith efforts to comply, any economic benefit gained by the violator as a result of its non-compliance, and a violator’s ability to pay.” – Civil Monetary Penalty Inflation Adjustment (40 CFR Part 19)

How technology helps become audit-ready

Proactive approach

The need to always be ready for an audit is less daunting when everything is accessible, and everyone is accountable from top to bottom throughout your organization. By automating the day-to-day activities, you have access to the data to guide and make real-time decisions to improve your facility and proactively address risks. With digital environmental and safety intelligence, tracking incomplete inspections or outstanding actions that need to be addressed are highlighted for managers and workers to see. And developing this accountability of everyone knowing and seeing the information, the potentially bigger issues can be addressed before they turn into a bigger problem, regulatory fines, or even a lawsuit. With that level of detail and transparency that you can share with your regulators, you’re able to build a relationship on trust and proactively working together.

Automatic and empowered

Technology provides a built-in audit trail and automated record-keeping for your team. As a result, you no longer worry about files or information getting lost, incomplete, inaccurate, or overlooked. Digital compliance of the EHS process further promotes accountability with everyone at your organization. From reporting, tracking to detecting any issues– your field team is no longer facing the “pencil whipping” of forms. They can easily use any smartphone, tablet, or computer to quickly capture inspections in the field, upload photos, log and assign corrective actions. As the management identifies any low-performing areas, they can quickly address how to correct the challenges the field workers are facing that inhibit them from completing their inspections as needed, and for those areas doing well, it’s easy to now see and recognize those sites. — Undoubtedly, the shift to digital can seem accelerated and complex, however, EHS intelligence drives accountability and collaboration through visibility in your organization. Having set controls and digital compliance drives an accurate, controlled, and consistent approach to every process. Intelligent automation allows for increased capacity and enables higher-value work as everyone isn’t buried under piles of papers with the information they can’t compare and use in real-time. By unifying systems and data for a complete EHS compliance story at your organization, you have the connections you need to be proactive and genuinely be audit-ready.